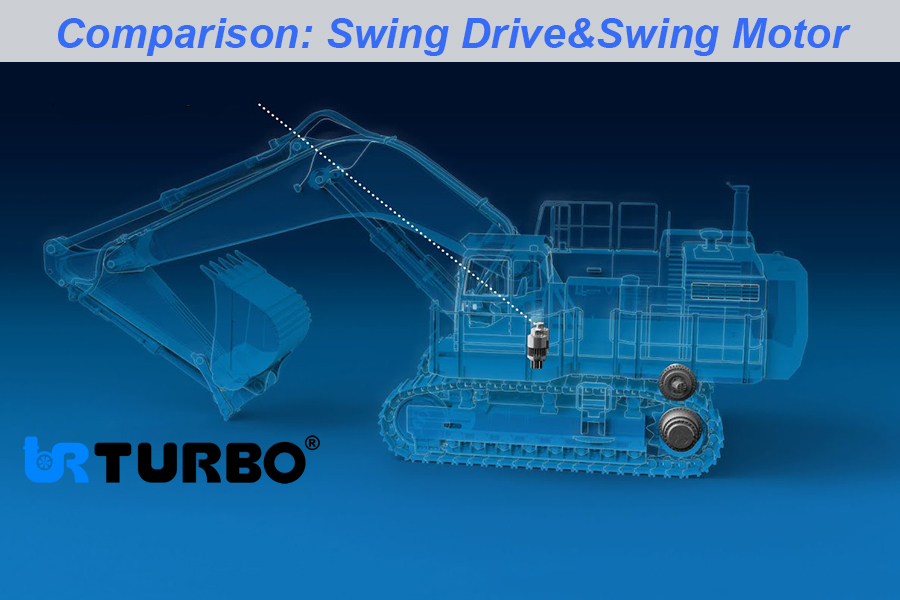

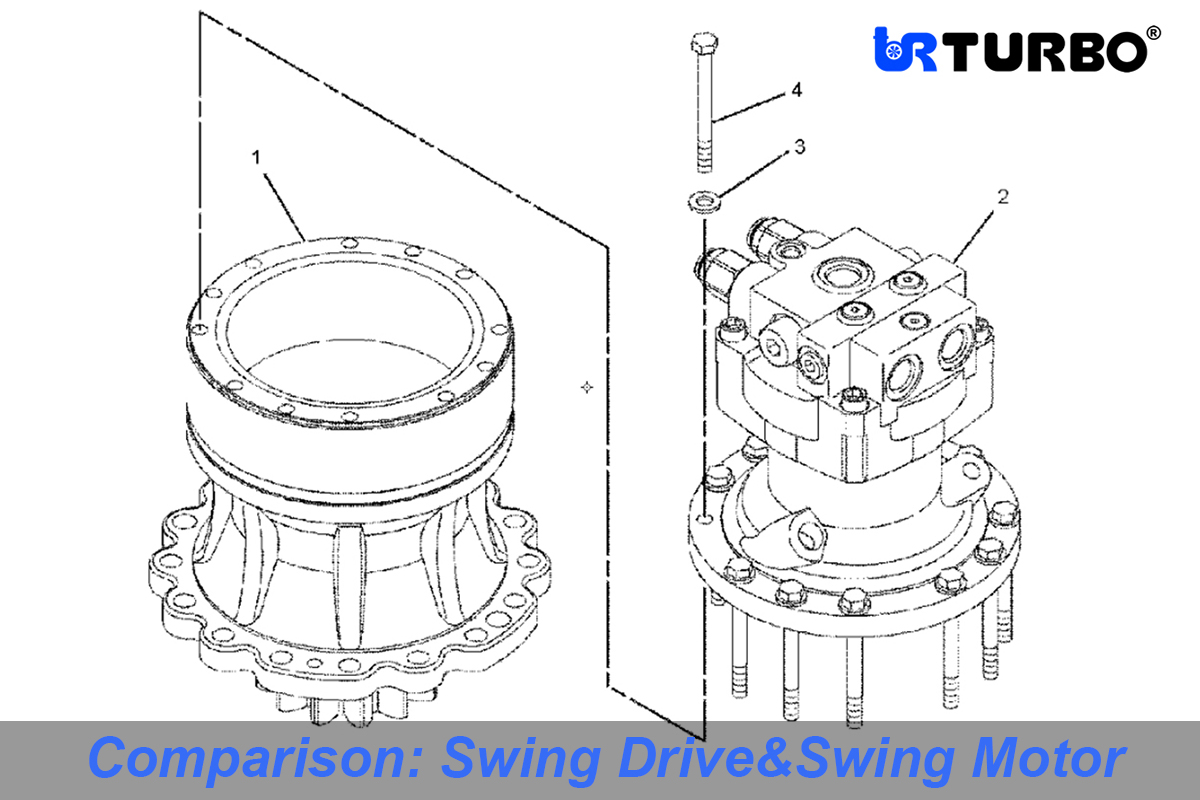

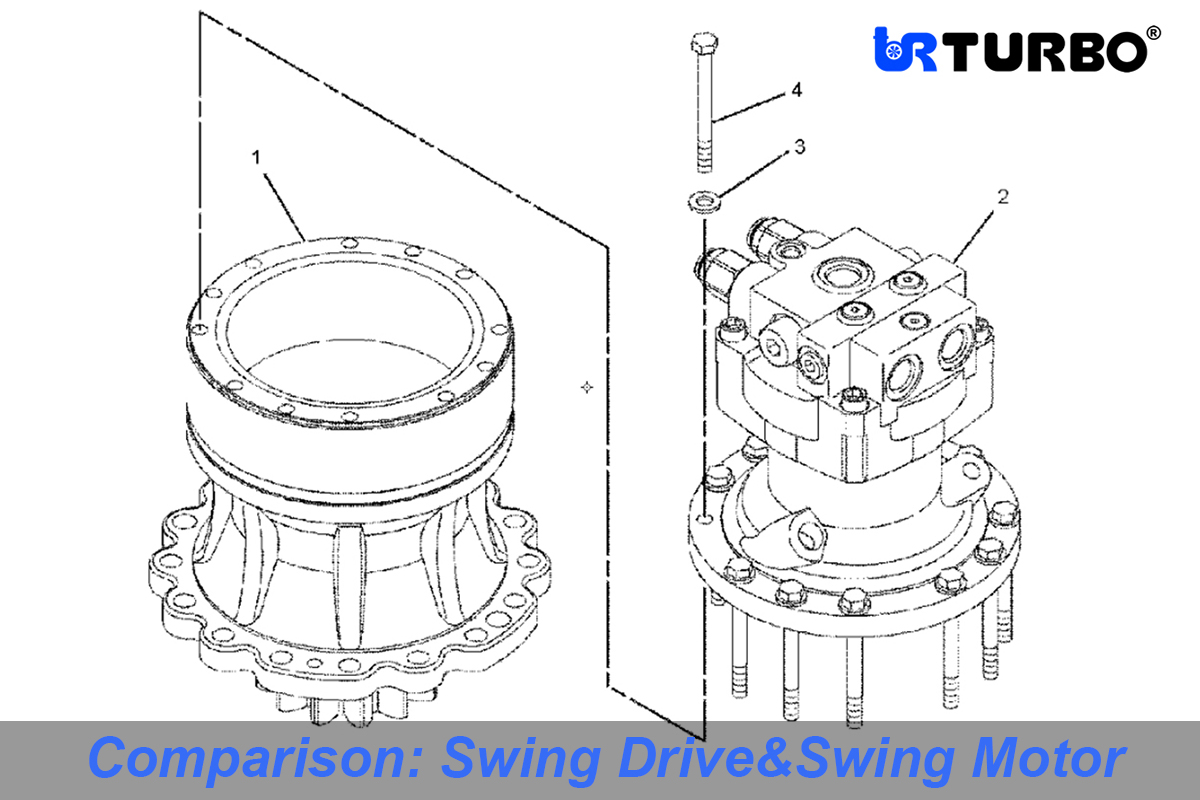

Comparison: Swing Drive&Swing Motor

When it comes to heavy machinery, particularly excavators and other construction equipment, the terms "swing drive" and "swing motor" are often used interchangeably. However, they refer to two distinct components that work together to enable the rotational movement of the machine's upper structure. Understanding the difference between a swing drive and a swing motor is crucial for anyone involved in the maintenance, repair, or operation of such equipment. In this blog, we’ll break down the roles, functions, and key differences between these two components.

What is a Swing Motor?

A swing motor is a hydraulic motor responsible for generating the rotational force needed to turn the upper structure of an excavator or similar machinery. It converts hydraulic energy (from the machine’s hydraulic system) into mechanical energy, which drives the rotation of the equipment. The swing motor is typically mounted on the machine’s frame and is connected to the swing drive.

Key Features of a Swing Motor:

Hydraulic Power Source: The swing motor relies on the machine’s hydraulic system to function. It uses pressurized hydraulic fluid to create rotational motion.

High Torque Output: Swing motors are designed to produce high torque, which is necessary for rotating the heavy upper structure of an excavator.

Compact Design: Despite their power, swing motors are relatively compact, making them suitable for the limited space within heavy machinery.

Variable Speed Control: Modern swing motors often feature variable speed control, allowing operators to adjust the rotation speed based on the task at hand.

What is a Swing Drive?

A swing drive, on the other hand, is a mechanical assembly that transmits the rotational force generated by the swing motor to the upper structure of the machine. It acts as a gearbox, amplifying the motor’s torque and ensuring smooth, controlled rotation. The swing drive is typically mounted between the upper structure (house) and the undercarriage of the machine.

Key Features of a Swing Drive:

Gear Reduction System: The swing drive uses a series of gears to reduce the speed of the swing motor’s output while increasing torque. This ensures the machine can handle heavy loads.

Slewing Ring Bearing: The swing drive incorporates a slewing ring bearing, which allows the upper structure to rotate smoothly relative to the undercarriage.

Durability: Swing drives are built to withstand extreme loads and harsh operating conditions, making them highly durable.

Integrated Design: In many modern machines, the swing drive is an integrated unit that combines the motor, gearbox, and bearing into a single compact assembly.

Key Differences Between a Swing Drive and a Swing Motor

While the swing motor and swing drive work together to enable rotational movement, they serve different purposes and have distinct characteristics. Here’s a breakdown of their differences:

|

Aspect |

Swing Motor |

Swing Drive |

|

Function |

Generates rotational force |

Transmits and amplifies rotational force |

|

Power Source |

Hydraulic system |

Mechanical (driven by the swing motor) |

|

Components |

Hydraulic motor, pistons, valves |

Gears, bearings, housing |

|

Role in Rotation |

Provides the initial torque |

Converts torque into controlled rotation |

|

Location |

Mounted on the machine’s frame |

Positioned between upper and lower structures |

|

Maintenance |

Requires hydraulic system checks |

Requires lubrication and gear inspection |

How They Work Together

The swing motor and swing drive are interdependent components that form the slewing system of heavy machinery. Here’s how they work together:

Hydraulic Power Generation: The machine’s hydraulic system supplies pressurized fluid to the swing motor.

Torque Generation: The swing motor converts the hydraulic energy into mechanical torque.

Torque Transmission: The swing motor’s output shaft is connected to the swing drive, which receives the rotational force.

Gear Reduction: The swing drive’s gear system reduces the speed of rotation while increasing torque.

Smooth Rotation: The slewing ring bearing within the swing drive allows the upper structure to rotate smoothly relative to the undercarriage.

Conclusion

In summary, the swing motor and swing drive are two essential components that work together to enable the rotational movement of heavy machinery. While the swing motor generates the necessary torque, the swing drive transmits and amplifies this force, ensuring smooth and controlled rotation. Understanding the differences between these components is crucial for proper maintenance and operation, ultimately extending the lifespan of the equipment and reducing downtime.

Whether you’re an operator, technician, or equipment owner, knowing how these components function and interact will help you keep your machinery running efficiently and effectively. So, the next time you hear someone mention a swing motor or swing drive, you’ll know exactly what they’re talking about—and why both are so important!