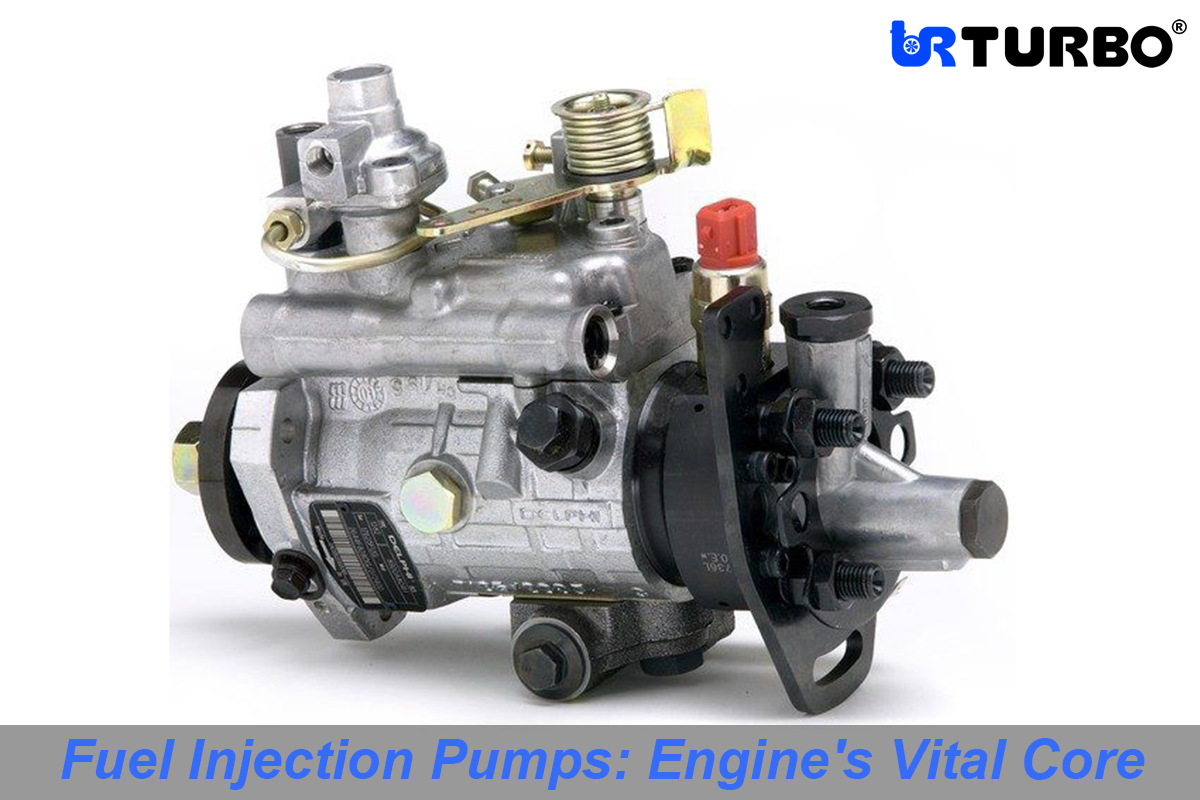

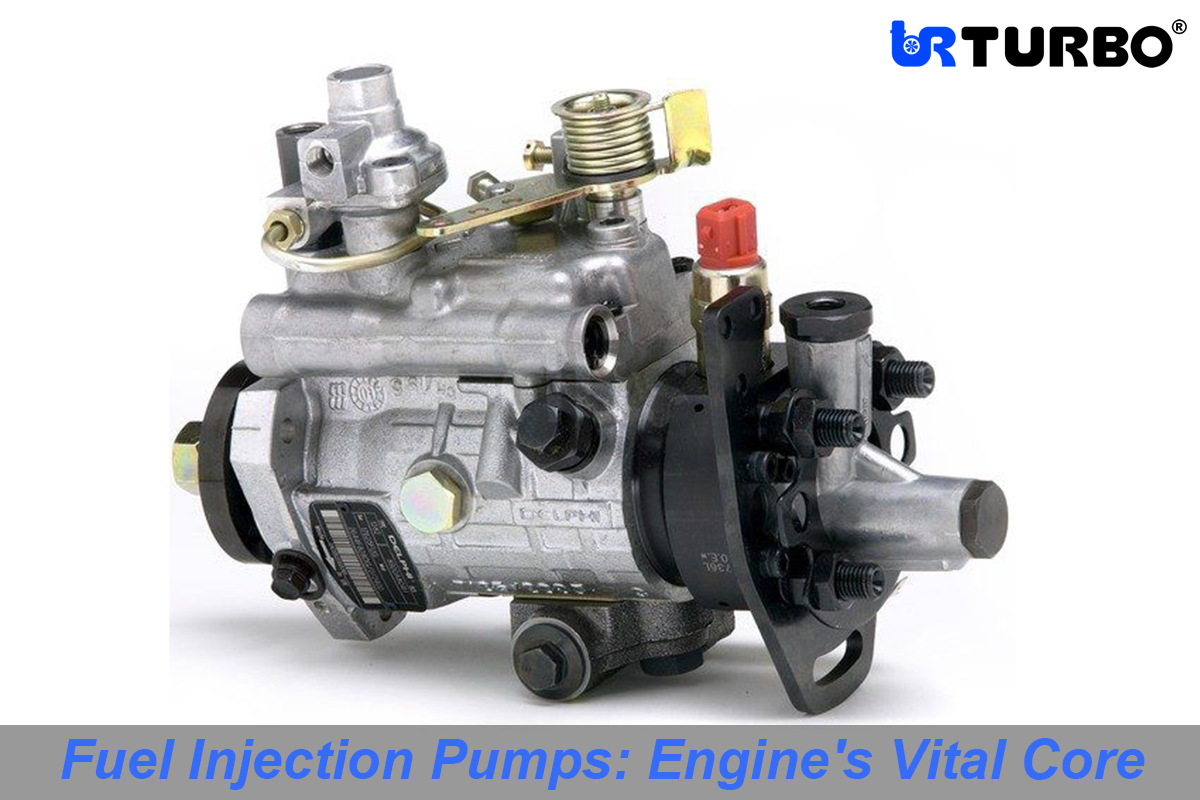

Fuel Injection Pumps: Engine's Vital Core

Fuel Injection Pumps: The Heart of Your Machine

In the world of internal combustion engines, few components are as critical to performance, efficiency, and reliability as the fuel injection pump. Often referred to as the "heart" of the machine, the fuel injection pump plays a pivotal role in ensuring that engines run smoothly, efficiently, and with minimal emissions. Whether in a car, truck, tractor, or industrial machinery, the fuel injection pump is a marvel of engineering that deserves a closer look.

In this blog, we’ll explore what fuel injection pumps are, how they work, their importance, and how to maintain them for optimal performance.

What is a Fuel Injection Pump?

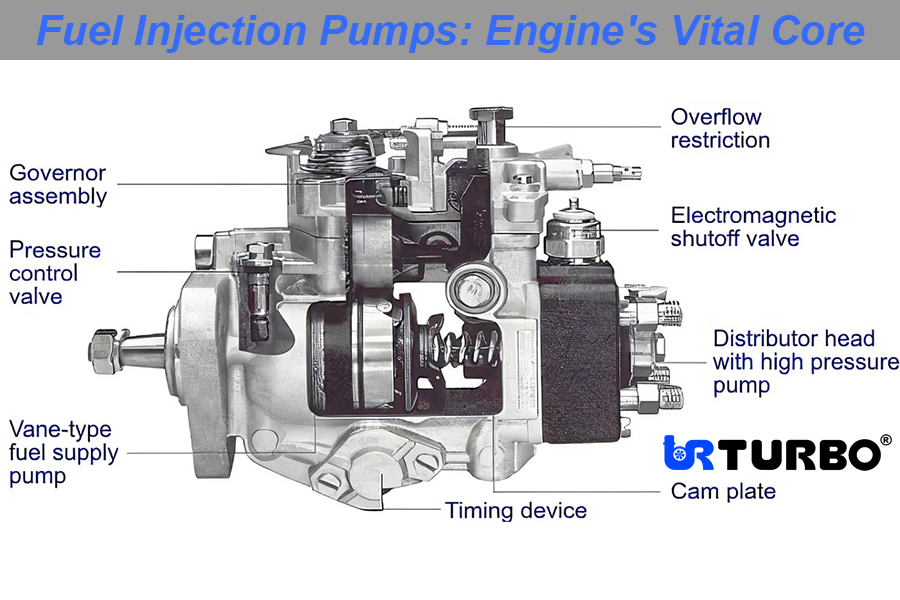

A fuel injection pump is a mechanical or electronic device responsible for delivering fuel to the engine’s combustion chambers at the right time, in the right quantity, and at the right pressure. It is a key component of diesel engines and modern gasoline engines that use direct injection systems. The pump ensures that fuel is atomized into a fine mist, allowing it to mix thoroughly with air for efficient combustion.

Fuel injection pumps have largely replaced older carburetor systems, which were less precise and less efficient. By delivering fuel directly into the engine’s cylinders or intake manifold, fuel injection pumps provide better control over the combustion process, leading to improved performance, fuel economy, and reduced emissions.

How Does a Fuel Injection Pump Work?

The operation of a fuel injection pump depends on the type of engine and the specific design of the pump. However, the basic principle remains the same: to deliver pressurized fuel to the engine. Here’s a simplified breakdown of how it works:

- Fuel Intake: The pump draws fuel from the fuel tank through a supply line.

- Pressurization: The fuel is pressurized to a high level, often exceeding 2,000 psi in diesel engines, to ensure proper atomization.

- Timing and Delivery: The pump delivers the pressurized fuel to the injectors at precisely the right moment in the engine’s combustion cycle.

- Atomization: The injectors spray the fuel into the combustion chamber or intake manifold, where it mixes with air and ignites.

- In modern engines, electronic control units (ECUs) work in tandem with the fuel injection pump to optimize fuel delivery based on factors like engine load, speed, and temperature. This level of precision ensures maximum efficiency and performance.

Types of Fuel Injection Pumps

There are several types of fuel injection pumps, each suited to different engine designs and applications:

- Inline Injection Pumps: Commonly used in older diesel engines, these pumps have a separate plunger for each cylinder and are known for their durability and simplicity.

- Distributor Pumps: These pumps use a single plunger to distribute fuel to all cylinders. They are more compact and lightweight, making them popular in smaller engines.

- Unit Injector Systems: In this design, the pump and injector are combined into a single unit. This system allows for precise control and is often used in heavy-duty diesel engines.

- Common Rail Systems: A modern innovation, common rail systems use a high-pressure rail to deliver fuel to electronically controlled injectors. This system offers unparalleled precision and is widely used in both diesel and gasoline engines.

Why Are Fuel Injection Pumps So Important?

The fuel injection pump is often called the "heart" of the machine because, like the human heart, it is essential for keeping the system alive and functioning. Here’s why it’s so important:

- Efficiency: By delivering the exact amount of fuel needed for combustion, fuel injection pumps maximize fuel efficiency and reduce waste.

- Performance: Precise fuel delivery ensures smooth engine operation, better acceleration, and consistent power output.

- Emissions Control: Proper atomization and combustion reduce harmful emissions, helping engines meet stringent environmental regulations.

- Reliability: A well-functioning fuel injection pump ensures that the engine runs reliably, even under demanding conditions.

Without a properly functioning fuel injection pump, an engine may experience poor performance, increased fuel consumption, excessive emissions, and even complete failure.

Signs of a Failing Fuel Injection Pump

Like any mechanical component, fuel injection pumps can wear out or fail over time. Recognizing the signs of a failing pump can help you address issues before they lead to costly repairs. Common symptoms include:

- Difficulty Starting the Engine: A weak or failing pump may not deliver enough fuel to start the engine.

- Loss of Power: Insufficient fuel delivery can cause the engine to lose power, especially under load.

- Poor Fuel Economy: A malfunctioning pump may deliver too much or too little fuel, reducing efficiency.

- Engine Misfires: Irregular fuel delivery can cause misfires or rough idling.

- Increased Emissions: A failing pump can lead to incomplete combustion, resulting in higher emissions.

If you notice any of these symptoms, it’s important to have your fuel injection pump inspected by a qualified technician.

Maintaining Your Fuel Injection Pump

Proper maintenance is key to ensuring the longevity and performance of your fuel injection pump. Here are some tips to keep it in top condition:

- Use Clean Fuel: Contaminants in fuel can damage the pump and injectors. Always use high-quality fuel and replace fuel filters regularly.

- Monitor Fuel Pressure: Low or inconsistent fuel pressure can indicate a problem with the pump. Have it checked if you notice any issues.

- Regular Inspections: Include the fuel injection pump in your routine engine inspections to catch potential problems early.

- Address Issues Promptly: If you notice any signs of a failing pump, don’t delay repairs. Ignoring the problem can lead to more extensive damage.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule and recommendations provided by your engine or vehicle manufacturer.

The fuel injection pump is indeed the heart of your machine, ensuring that your engine runs efficiently, powerfully, and cleanly. From its precise fuel delivery to its role in reducing emissions, this critical component deserves attention and care. By understanding how it works, recognizing the signs of failure, and maintaining it properly, you can keep your engine running smoothly for years to come.