Precautions for Excavators in Spring

As the winter frost melts away and the first signs of spring emerge, construction sites come back to life. Excavators, which may have been idle or underutilized during the colder months, are now back in action. However, transitioning from winter to spring operations requires careful attention to ensure the safety, efficiency, and longevity of your equipment. In this blog, we’ll explore essential precautions and maintenance tips for excavators during the spring season.

Why Spring Maintenance Matters

Spring is a critical time for excavator maintenance. The fluctuating temperatures, increased moisture, and muddy conditions can take a toll on heavy machinery. Without proper care, equipment can suffer from accelerated wear and tear, leading to costly repairs and downtime. By taking proactive steps, you can ensure your excavator operates smoothly throughout the busy construction season.

Spring Excavator Precautions

Inspect for Winter Damage

After a long winter, your excavator may have accumulated damage from freezing temperatures, snow, and ice. Before starting spring operations, conduct a thorough inspection:

1.Check for cracks in the hydraulic hoses, which can become brittle in cold weather.

2.Inspect the undercarriage for rust or corrosion caused by snow and salt.

3.Examine the bucket and attachments for signs of wear or damage.

Beware of Thawing Ground

Spring often brings muddy and unstable ground conditions. Operating an excavator on soft or uneven terrain can lead to accidents or equipment getting stuck. To mitigate risks:

1.Use wider tracks or pads to distribute the machine’s weight and reduce ground pressure.

2.Avoid operating too close to the edges of trenches or slopes, as the ground may be unstable.

3.Always assess the worksite for potential hazards before starting work.

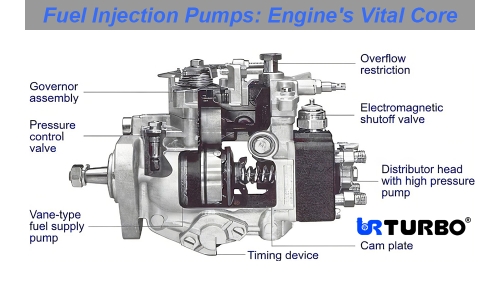

Monitor Hydraulic Systems

Hydraulic systems are the lifeblood of an excavator, and they can be particularly vulnerable during seasonal transitions. Cold weather can cause hydraulic fluid to thicken, while warmer temperatures may lead to leaks or pressure issues. To prevent problems:

1.Check hydraulic fluid levels and top up if necessary.

2.Inspect for leaks or damaged seals.

3.Ensure the hydraulic system is functioning smoothly before heavy use.

Stay Alert for Weather Changes

Spring weather can be unpredictable, with sudden rain showers or temperature swings. These conditions can affect both operator safety and equipment performance. Always:

1.Keep an eye on the weather forecast and plan work accordingly.

2.Ensure the excavator’s cab is equipped with proper wipers, defrosters, and lighting for visibility in rain or fog.

3.Avoid operating in severe weather conditions that could compromise safety.

Train Operators for Spring Conditions

Spring brings unique challenges that require operators to adapt their techniques. Ensure your team is trained to handle:

1.Slippery or muddy terrain.

2.Reduced visibility due to rain or fog.

3.Proper use of attachments for spring-specific tasks, such as clearing debris or grading soft soil.

Spring Excavator Maintenance Suggestions

Clean and Degrease

Winter grime, salt, and mud can accumulate on your excavator, leading to corrosion and reduced performance. A thorough cleaning is essential:

1.Use a pressure washer to remove dirt and debris from the undercarriage, tracks, and attachments.

2.Degrease moving parts to prevent buildup that can hinder performance.

3.Apply a protective coating or wax to exposed metal surfaces to guard against rust.

Lubricate Moving Parts

Proper lubrication is crucial for keeping your excavator running smoothly. Spring is an ideal time to:

1.Grease all pivot points, joints, and bearings to reduce friction and wear.

2.Check the lubrication system for any blockages or malfunctions.

3.Use high-quality lubricants suitable for the specific components of your excavator.

Check and Replace Filters

Filters play a vital role in protecting your excavator’s engine and hydraulic systems. Over time, they can become clogged with dirt and debris. During spring maintenance:

1.Inspect and replace air, fuel, and hydraulic filters as needed.

2.Clean or replace the cabin air filter to ensure a safe and comfortable environment for the operator.

Inspect the Undercarriage

The undercarriage is one of the most critical and expensive components of an excavator. Spring’s wet and muddy conditions can accelerate wear and tear. To maintain the undercarriage:

1.Check for loose or damaged track links, rollers, and idlers.

2.Remove debris stuck in the tracks to prevent unnecessary strain.

3.Ensure proper track tension to avoid slippage or excessive wear.

Test the Battery

Cold weather can take a toll on your excavator’s battery, reducing its capacity and lifespan. Before spring operations:

1.Test the battery’s voltage and charge level.

2.Clean the terminals and connections to prevent corrosion.

3.Replace the battery if it shows signs of weakness or damage.

Review Fluid Levels

Fluids are essential for the proper functioning of your excavator. As part of your spring maintenance routine:

1.Check and top up engine oil, coolant, and hydraulic fluid.

2.Inspect for any signs of contamination, such as water in the hydraulic fluid.

3.Replace fluids if they are due for a change or show signs of degradation.

Inspect Attachments

Excavator attachments, such as buckets, breakers, and grapples, are subject to heavy use and wear. Before the busy spring season:

1.Inspect attachments for cracks, bends, or other damage.

2.Replace worn teeth or cutting edges on buckets.

3.Ensure all attachments are properly secured and functioning.

Schedule Professional Servicing

While regular operator maintenance is essential, it’s also a good idea to have your excavator professionally serviced at the start of the spring season. A trained technician can:

1.Perform a comprehensive inspection of all systems.

2.Identify and address potential issues before they become major problems.

3.Ensure your excavator is in peak condition for the demands of spring work.

Conclusion

Spring is a time of renewal, and that includes your excavator. By taking the necessary precautions and performing thorough maintenance, you can ensure your equipment is ready to tackle the challenges of the season. Not only will this improve safety and efficiency on the job site, but it will also extend the lifespan of your excavator, saving you time and money in the long run. Remember, a well-maintained machine is a reliable partner in any construction project. Happy digging!