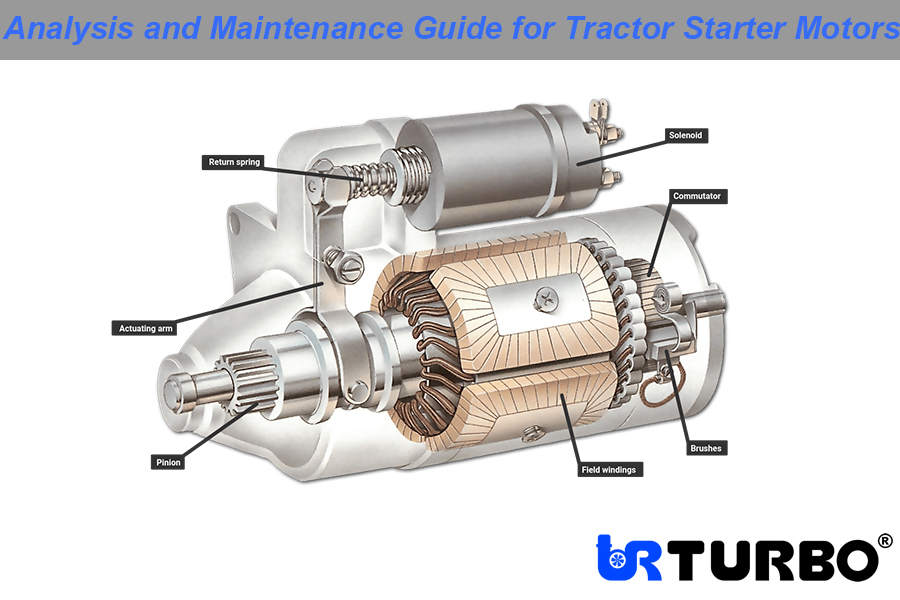

Analysis and Maintenance Guide for Tractor Starter Motors

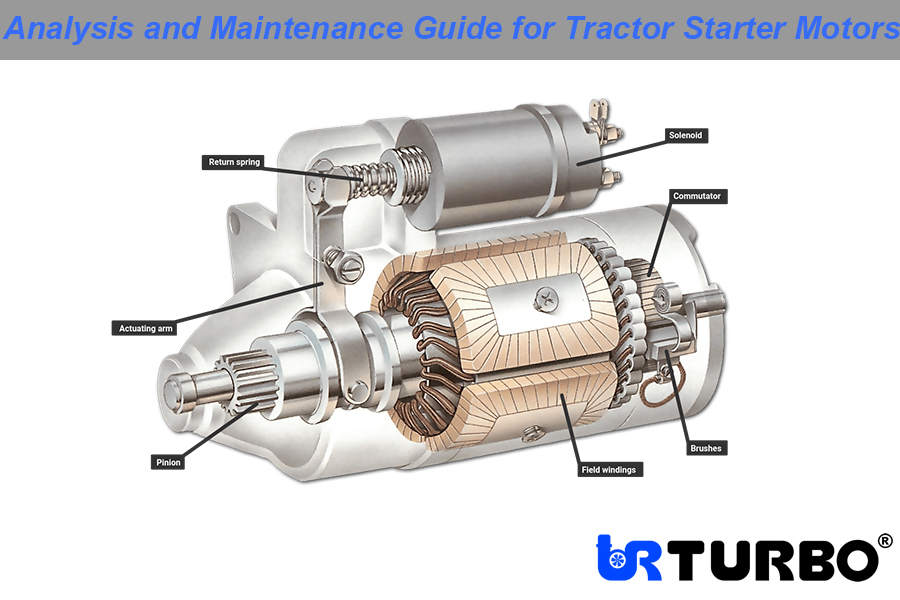

1. What is a starter motor

A starter motor, also known as a starter, is an important part of the starting system for tractors and other internal combustion engine vehicles. It is a device that converts electrical energy into mechanical energy to start the engine by driving the engine's flywheel to rotate.

2. Principle of operation of the starter motor

The principle of operation of a starter motor is based on electromagnetic induction. When an electric current passes through the coil of the starter motor, a magnetic field is generated, which interacts with the electric current to produce a torque that drives the rotor of the starter motor to rotate. The rotor is connected to the engine's flywheel. When the rotor rotates, the flywheel rotates with it, thus starting the engine.

3. Wiring of the starter motor

The wiring of a starter motor usually consists of three main parts: the power supply, the starter switch and the starter motor. The power source is usually an electric battery, the starter switch is usually located in the cab, and the starter motor is mounted near the engine. When wiring, make sure that the positive terminal of the power supply is connected to the positive terminal of the starter motor, the negative terminal is connected to the negative terminal of the starter motor, and the starter switch is connected to the starter motor's control wire.

4. Common starter motor faults and their repair methods

Common faults of the starter motor include failure to start, weak start, strange noise, etc. The cause of the fault may be the battery charge. The cause of the failure may be insufficient battery power, starter motor damage, loose wiring and so on.

Repair methods include checking the battery level, replacing the starter motor, checking and tightening the wiring, etc.

5. Maintenance knowledge of starter motor

As a key component of the tractor starting system, the performance and life span of the starter motor directly affects the efficiency and cost of the tractor. Therefore, regular maintenance and proper use of the starter motor are important measures to extend its service life and ensure its normal operation.

Periodically check the wiring of the starter motor for firmness to prevent problems such as weak starting or failure to start caused by loose wiring. Also, check the appearance of the starter motor for damage, cracks, etc., as well as for abnormalities such as oil and electrical leaks.

Keep the exterior of the starter motor clean to avoid dust, oil and other debris from entering the interior of the starter motor and affecting its performance and life. When cleaning, you can use a wet cloth to wipe and avoid using water for direct rinsing.

Regularly apply the proper amount of grease to the bearings and transmission parts of the starter motor to reduce wear and prolong service life. The choice of grease should be based on the specific requirements of the starter motor and the environment in which it will be used.

When the starter motor fails, it should be stopped immediately and repaired in time. You can refer to the instruction manual of the starter motor or ask the professional maintenance personnel to deal with the malfunction judgment and maintenance.

Through the above maintenance measures, you can ensure the normal work of the starter motor, extend its service life, reduce maintenance costs, and improve the efficiency of the tractor.

How to choose a starter motor?

Firstly, ensure the applicability of the accessories to the machine: make sure the starter motor matches the engine model of the tractor, as well as matching the starter motor according to the engine displacement and power requirements.

Second, the quality and performance of the starter motor is an important consideration for customers. Look for starter motors that use durable materials, such as high-quality gears and sturdy housings.

Finally, choose a business with good after-sales service so that problems can be resolved in a timely manner.

Why choose Urturbo

Superior Quality and Reliability

Durable Construction: Our starter motors are built with high-quality materials, ensuring long-lasting performance even under demanding conditions.

Rigorous Testing: Each starter motor undergoes strict quality control and testing to guarantee reliability and efficiency.

Wide Compatibility

Extensive Range: We offer starter motors compatible with a wide variety of vehicles, including cars, trucks, motorcycles, boats, and heavy machinery.

Precise Fit: Our products are designed to meet OEM specifications, ensuring seamless installation and optimal performance.

Exceptional Customer Support

Expert Assistance: Our team of professionals is available to provide guidance and support, helping customers choose the right starter motor for their needs.

Warranty Coverage: We stand behind our products with comprehensive warranty options, giving customers peace of mind.

Global Availability

Wide Distribution Network: Our starter motors are readily available through a global network of distributors and retailers, ensuring quick and easy access.

Fast Shipping: We prioritize timely delivery to minimize downtime and keep customers on the road.